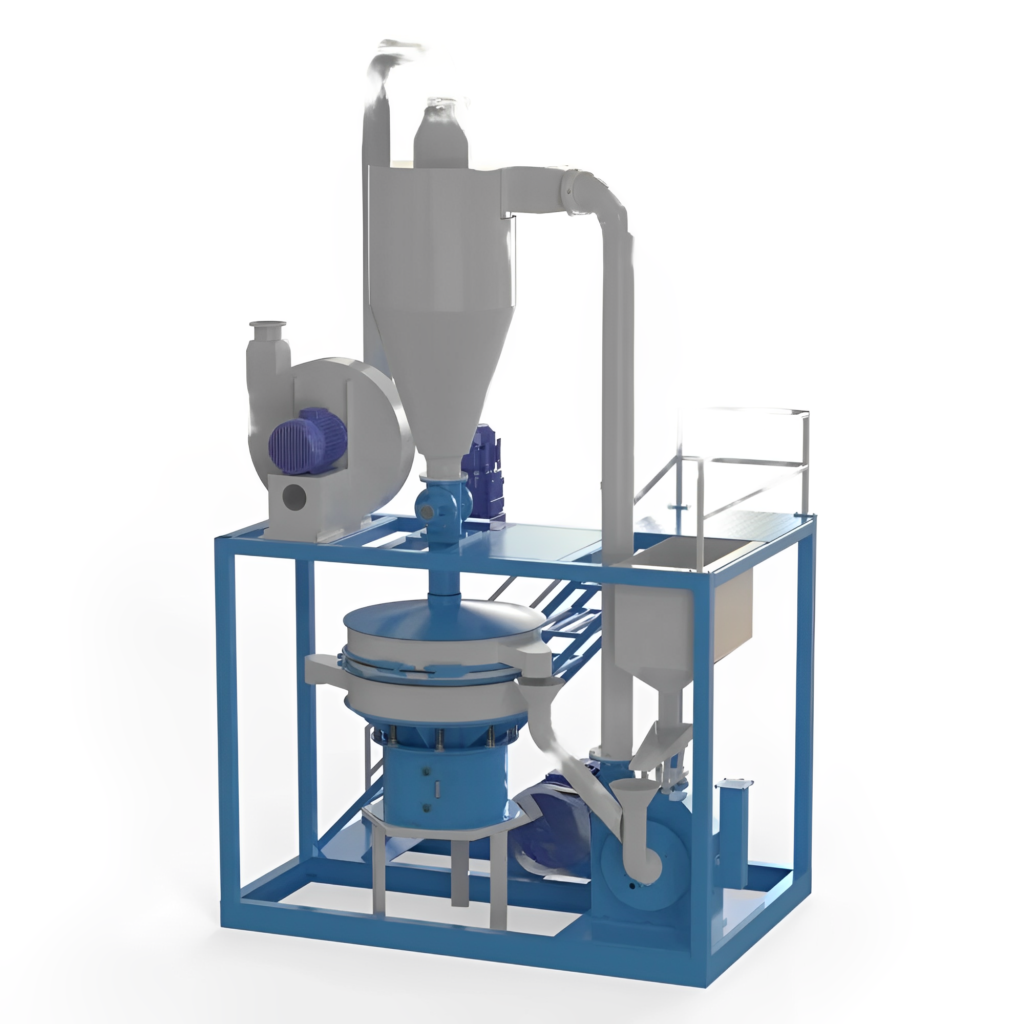

PVC Pulverizer

PVC Pulverizer is mainly used for the plastic chemical industry and has the characteristics of high yield, fine granularity, machinable grinding PVC, polyethylene, polystyrene PS, PVC, SBS and EVA, soft PVC, and other materials.

In plastic reprocessing after the types of plastic separate is mechanical processing to run the plastic through the pulverizer. Pulverizer or pulverizer crushes the plastic into tiny shreds or granules. A plastic pulverizer is a particular piece of equipment for recycling disused insignificant materials in producing and grinding heat-sensitivity plastic such as PVC.

The pulverizer includes high-output units which can be equipped with automatic temperature control. The material to be pulverized is fed centrally between a fixed and a high-speed rotating pulverizer disc with a centrifugal effect carrying the material through the processing zone before being discharged from the machine pneumatically. This pulverizer is mainly used for lldpe , hdpe, rpvc material.

The pulverizer includes high-output units which can be equipped with automatic temperature control. The material to be pulverized is fed centrally between a fixed and a high-speed rotating pulverizer disc with a centrifugal effect carrying the material through the processing zone before being discharged from the machine pneumatically.

- Advantage

- Using new cutting tool structure, improve the production and strengthen the cutting tool wear resistance

- High yield, fine flour, energy conservation, and environmental protection

- Applicability is wide and grinding can be PVC, PS, PA, PC, and other plastic

- Easy installation and maintenance, Opening the door cover can clean up and replace the tool

- The whole process fully sealed plastic flour, with no dust pollution

- 10-120 mesh powder size is adjustable, and convenient adjustment

- Plastic grinder cooling system which is based on wind, water cooling