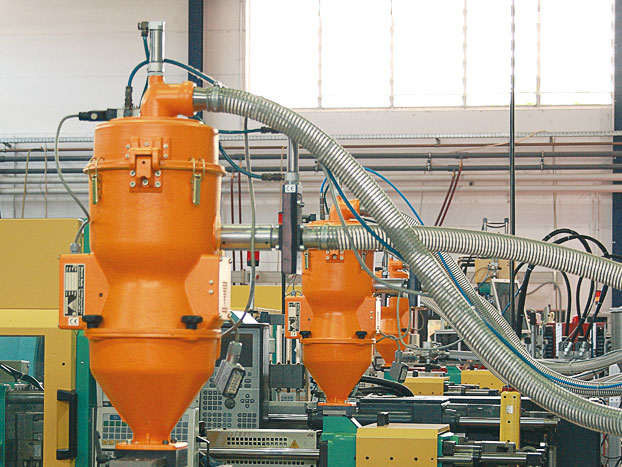

Central Conveying System

Central Conveying Systems work using the vacuum conveying principle. In the closed conveying system. the material is transported automatically, from the central, storage room to each processing machine. If a hopper loader indicates a need, the conveying process is started. a level sensor or by time. For vacuum generation, high performance blowers or pumps are used. Dust or fines are tittered out with a safely filter. This provides protection for the pump.

For central conveyor systems, spear offers you a host of components for all kinds of plastics processing from warehousing solutions to processing in injection moulding machines & extruder machine. The interaction between these components makes a significant contribution to the quality of the end product.

Our central vaccum conveying system also called centralized pneumatic supply system. It can be completely customized to your plastics processing to fullfill the target of continuous operation without downtimes.

- Advantages

Features :

- Completely tailored to your plastics processing

- Optimal hall utilization

- Central material management without the danger of confusion

- Cost-saving, with less personnel

- Clean production due to no residues on the machines

- Very short payback period

- Easy integration of plastic pellet dryers and central mixers

- Central material control system possible

- Continuous operation without downtimes

- The modularity makes the system expandable and future-proof