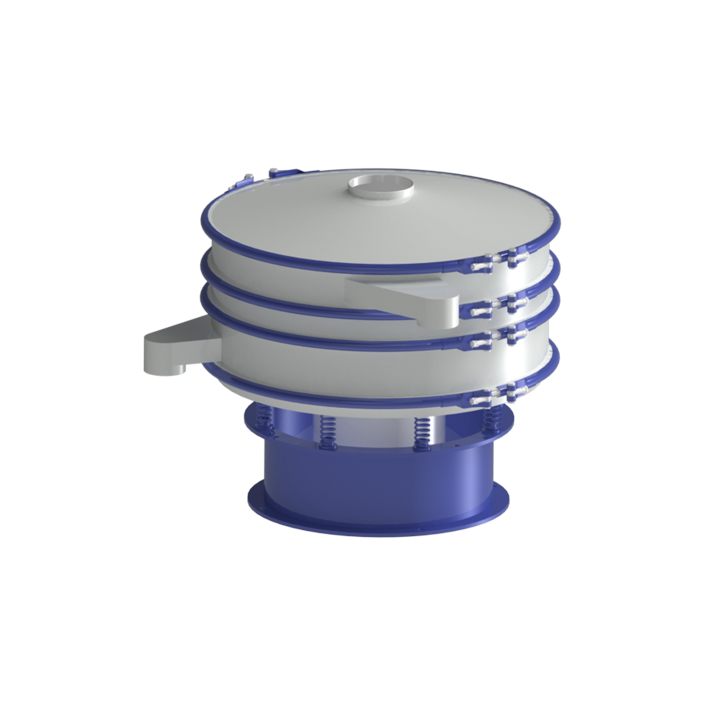

Gyro Screen

Invoit Plast Machinery Pvt Ltd screening problems such as sieving, grading, separating, screening, or scalping bulk materials. It can easily be installed into production lines, providing the best screening capacity without demanding excessive floor area. It has been designed to adjust easily allowing complete material control to optimize separation quality. Discharge outlets can also be moved around the machine giving greater flexibility in the positioning of collection bins or containers. Its modular nature segregates it from other models in terms of flexibility and optimum use of space.

Options of a fully stainless steel base or painted base are available on this gyro sieve separator. This machine’s stainless base is ideal where there is a need to regularly wash down the machine or where painted equipment is not permitted. This is a common requirement within the food or pharmaceutical industries where a hygienic design is essential. A fully stainless steel unit with contact parts in 316 stainless steel is available to provide increased durability which is ideal for corrosive and aggressive environments. A wide range of Gyro screens is available to suit your requirements.

The gyro screens are designed with multi-directional vibrators which prevent the blinding of sieves. The screen works on the principle of gyratory motion. Circular vibrating screens are the most progressive design of screens for grading fine, wet, and difficult-to-screen materials. These are designed in such a manner that, these screens can handle a wide range of materials including heavy, light, dry, wet, or fine.

- APPLICTIONS

- Features

- Plastic and Polymer Industry

- Minerals and Metals Industry

- Pharmaceuticals Industry

- Herbal and Chemical Industry

- Chemical

- Ceramic

- Dairy Industry

- Soap and Detergent

- Low Space Requirements

- Lower Noise Levels

- Dust Proof Enclosed System

- Accurate Separation Efficiency

- Greater Capacity

- Minimum Blinding

- Longer Screen Life

- No Transmitted Vibration